| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 18V631

Manufacturer Mazda North American Operations

North American Operations

Components SUSPENSION, STRUCTURE

Potential Number of Units Affected 48,814

Road Salt Causing Corrosion of Cross Member

Corrosion may weaken the mounting point for the passenger side lower control arm, unexpectedly changing the steering alignment and increasing the risk of a crash.

Summary

Mazda North American Operations (Mazda

North American Operations (Mazda ) is recalling certain 2009-2010 Mazda

) is recalling certain 2009-2010 Mazda Mazda6 vehicles sold, or ever registered in Connecticut, Delaware, Illinois, Indiana, Iowa, Kentucky, Maine, Maryland, Massachusetts, Michigan, Minnesota, Missouri, New Hampshire, New Jersey, New York, Ohio, Pennsylvania, Rhode Island, Vermont, Virginia, West Virginia, Wisconsin and the District of Columbia. The front cross member may corrode after exposure to road salt.

Mazda6 vehicles sold, or ever registered in Connecticut, Delaware, Illinois, Indiana, Iowa, Kentucky, Maine, Maryland, Massachusetts, Michigan, Minnesota, Missouri, New Hampshire, New Jersey, New York, Ohio, Pennsylvania, Rhode Island, Vermont, Virginia, West Virginia, Wisconsin and the District of Columbia. The front cross member may corrode after exposure to road salt.

Remedy

Mazda will notify owners, and dealers will inspect the cross member and either install a side member and drain hose and apply wax to protect from rust, or install a drain hose and an improved front cross member, free of charge. The recall is expected to begin November 12, 2018. Owners may contact Mazda

will notify owners, and dealers will inspect the cross member and either install a side member and drain hose and apply wax to protect from rust, or install a drain hose and an improved front cross member, free of charge. The recall is expected to begin November 12, 2018. Owners may contact Mazda customer service at 1-800-222-5500 Option 4. Mazda

customer service at 1-800-222-5500 Option 4. Mazda ’s number for this recall is 2818I.

’s number for this recall is 2818I.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Mazda has a Recall

2009-2010 Mazda6 – Front Cross Member Corrosion Concern Recall Campaign 2818I

A. INTERIM VEHICLE INSPECTION PROCEDURE UNTIL PARTS ARE AVAILABLE

- Subject vehicles

2009 Mazda6 (HP) and 2010 Mazda6 (HZ) vehicles, which were originally sold in, or currently or previously registered in Salt Belt States listed below.

| 23 “Salt Belt” States: | ||||

| Connecticut | Delaware | District of Columbia | Illinois | Indiana |

| Iowa | Kentucky | Maine | Maryland | Massachusetts |

| Michigan | Minnesota | Missouri | New Hampshire | New Jersey |

| New York | Ohio | Pennsylvania | Rhode Island | Vermont |

| Virginia | West Virginia | Wisconsin | ||

| Model | Subject VIN range | Subject production date range |

| 2009-2010MY Mazda6 | 1YV HP**** 95 M00001 – M52259

1YV HZ**** A5 M00014 – M58879 | From February 4, 2008 through October 1, 2010 |

The asterisk symbol “*” can be any letter or number.

- If the vehicle is within the above ranges, proceed to Step 2.

- If the vehicle is not within the above ranges, return vehicle to the customer or inventory.

Perform a Warranty Vehicle Inquiry using your eMDCS System and inspect vehicle for Campaign Labels Recalls 2818I attached to the vehicle’s hood or bulkhead. Refer to eMDCS System – Warranty Vehicle Inquiry Results table below.

NOTE: Be sure to verify Recall number as the vehicle may have multiple Recall labels.

eMDCS System – Warranty Vehicle Inquiry Results:

| If eMDCS displays: | Campaign Label is: | Action to perform: |

| RECALL 2818I OPEN | Present | Contact the Warranty Hotline at (877) 727-6626 option 3 to update vehicle history. |

| Not present | Proceed to “B. REPAIR PROCEDURE”. | |

| RECALL 2818I CLOSED | Present | Return vehicle to inventory or customer. |

| Not present | Proceed to “C. CAMPAIGN LABEL INSTALLATION”. | |

| RECALL 2818I IS NOT PRESENT | Does not apply | Recall does not apply to this vehicle. Return vehicle to inventory or customer. |

B. CROSS MEMBER INSPECTION PROCEDURE 2009-2010 MAZDA6

On certain subject vehicles in salt belt states, it is possible that the front cross member may be corroded due to possible insufficient paint coating. Corrosion may be more severe on the portion just under the air conditioner drain, causing a perforation.

Continued use of the vehicle with such condition may allow the perforation to progress, and the support of the right lower control arm front bushing to decrease. This may result in a change of the right front wheel alignment.

The vehicle having such conditions may exhibit the concerns as described below.

- Vehicle stability concerns (steering wheel off center, and pull to right side while driving/braking in a straight line)

- The Right Front tire may interfere with the mud guard, causing an abnormal noise and vibration.

- Cross member may fracture due to a heavy impact with a large pothole etc. Under high speed driving with such condition, it is possible that the steering control may become difficult.

Check the condition of the cross member, and determine if it is OK or Not OK based on the inspection criteria.

OK: No perforation due to corrosion exists in the specific areas of the cross member.

NOT OK: Perforation due to corrosion exists in the specific area(s) of cross member

If a rust hole exists in the specific area, the cross member may be broken due to a heavy impact with a large pothole

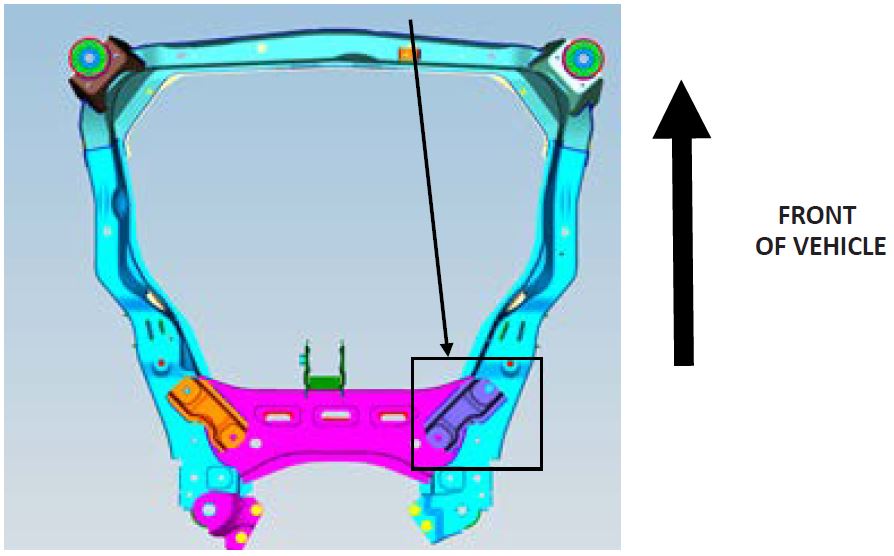

- If even one hole exists at the inspection areas Zone No.1 to Zone No.3 the vehicle will require replacement of the cross member.

- If a hole exists in an area other than Zone No.1 to Zone No.3, the structural rigidity of the cross member can be maintained through the installation of a reinforcement side member and a new A/C drain hose and the application of an Anti-Rust Cavity wax.

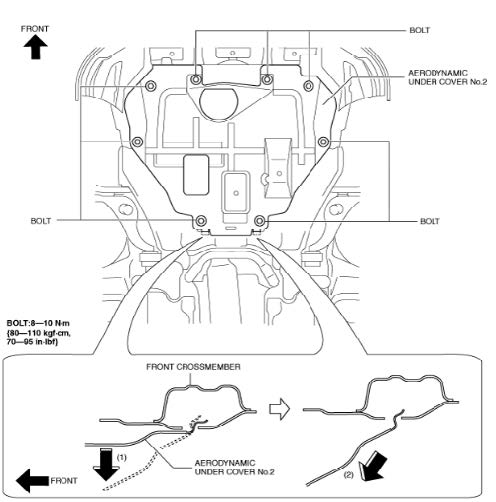

- Remove the Aerodynamic under cover No.2 for I4 engine vehicles. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)

Note: There is no Aerodynamic under cover No.2 for V6 engine vehicles.

- Remove the right front tire.

- Remove visible clips of side cover of right front tire house. Then bend the side cover so that Inspection point Zone No.1: Upper surface of the cross member can be seen

- Inspection contents

Check for perforation at all three areas by visual inspection: Top Surface, Inside and Side.

If the even one hole exists at these points Zone No.1 to Zone No.3, the vehicle needs replacement of cross member.

Meanwhile, even if there are holes at other places, except holes at Zone No.1 to Zone No. 3 points, the vehicle doesn’t need replacement of the cross member. Instead, the subject vehicle will require the installation of the reinforcement side member and the A/C drain hose and wax application.

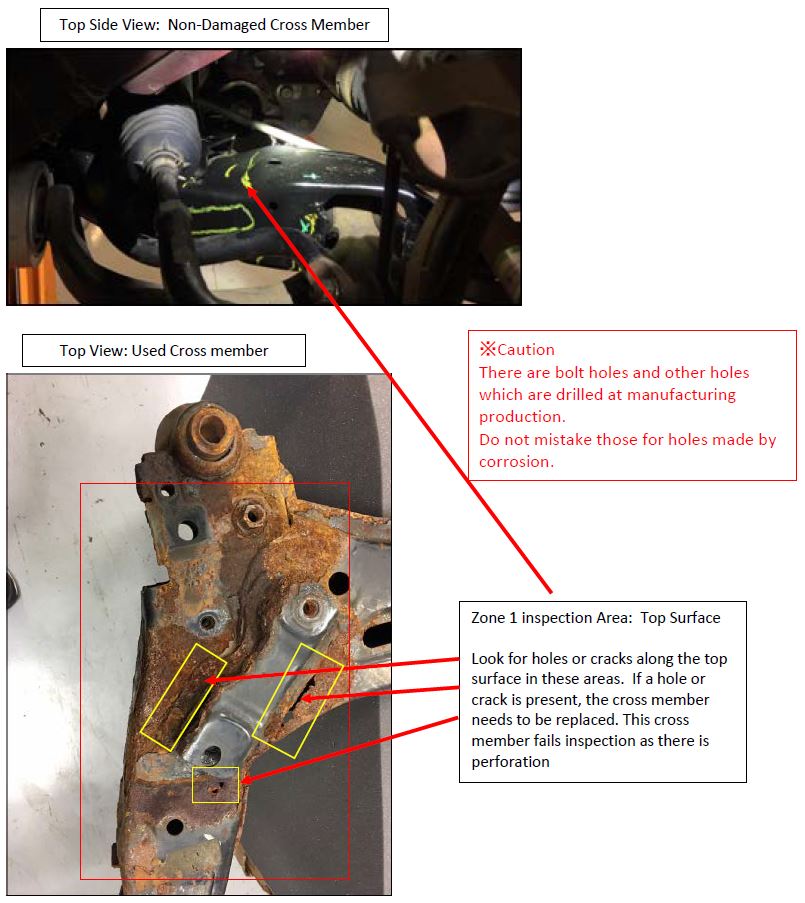

Top View – Area affected (Right Top Side)

Zone 1 Inspection – Upper Surface/Top side

If the cross member fails inspection in this Zone, take a clear photo showing the failure. You will need it for later.

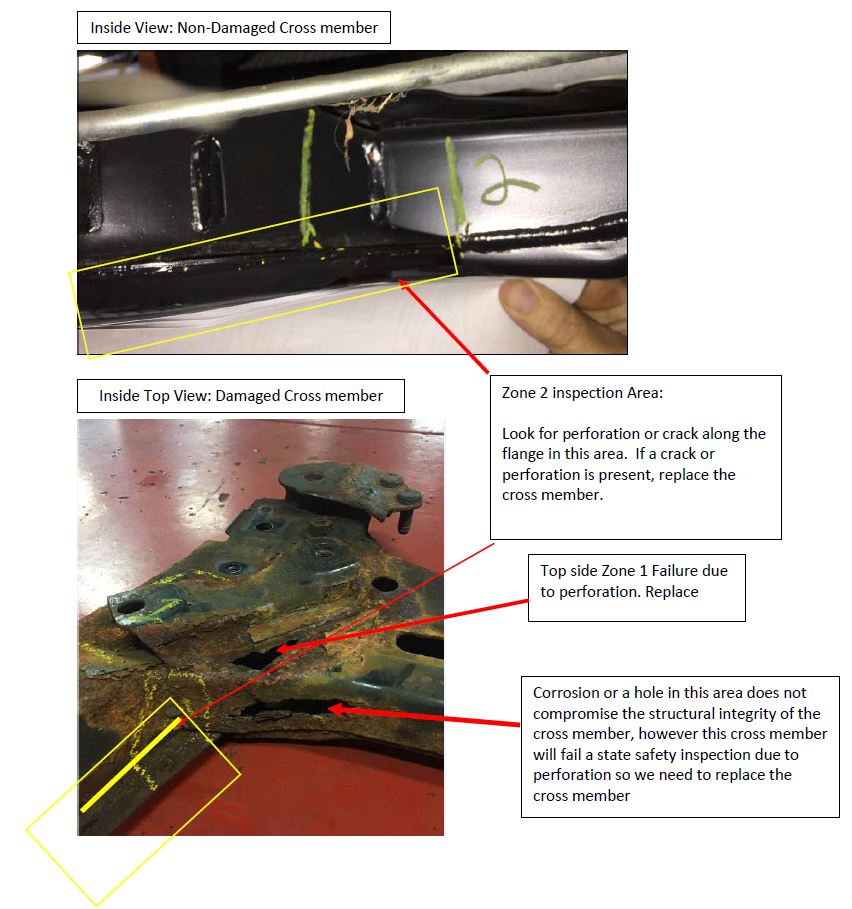

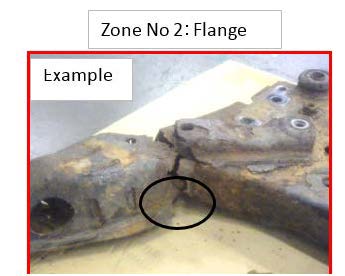

Zone 2 Inspection – Inside Corner/Flange Weld

If the cross member fails inspection in this Zone, take a clear photo showing the failure. You will need it for later.

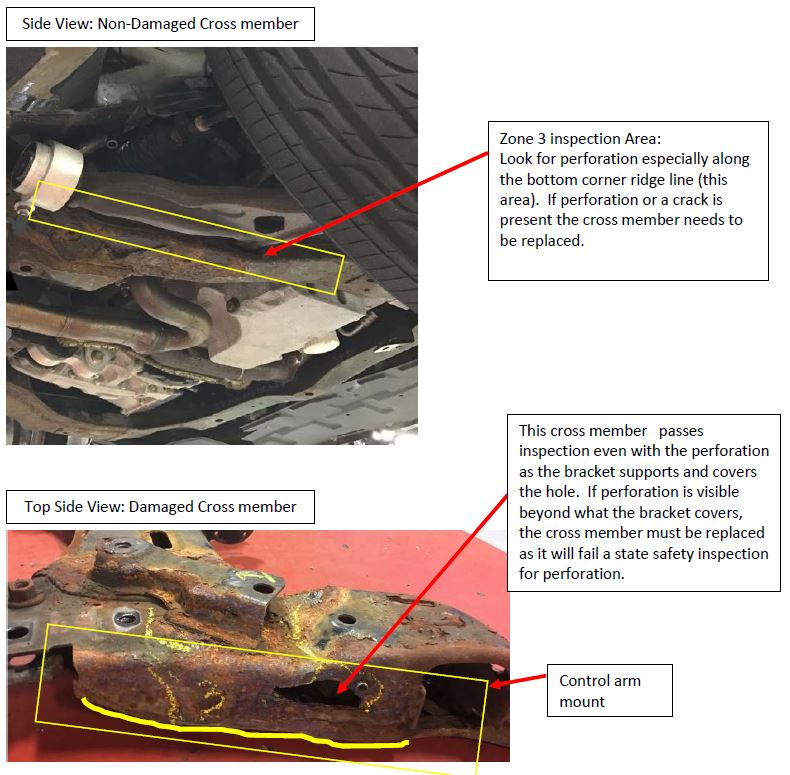

Zone 3 Inspection – Outer Area

If the cross member fails inspection in this Zone, take a clear photo showing the failure. You will need it for later.

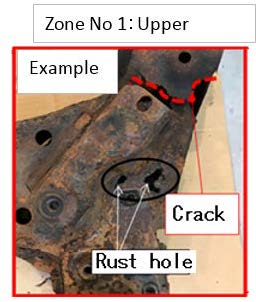

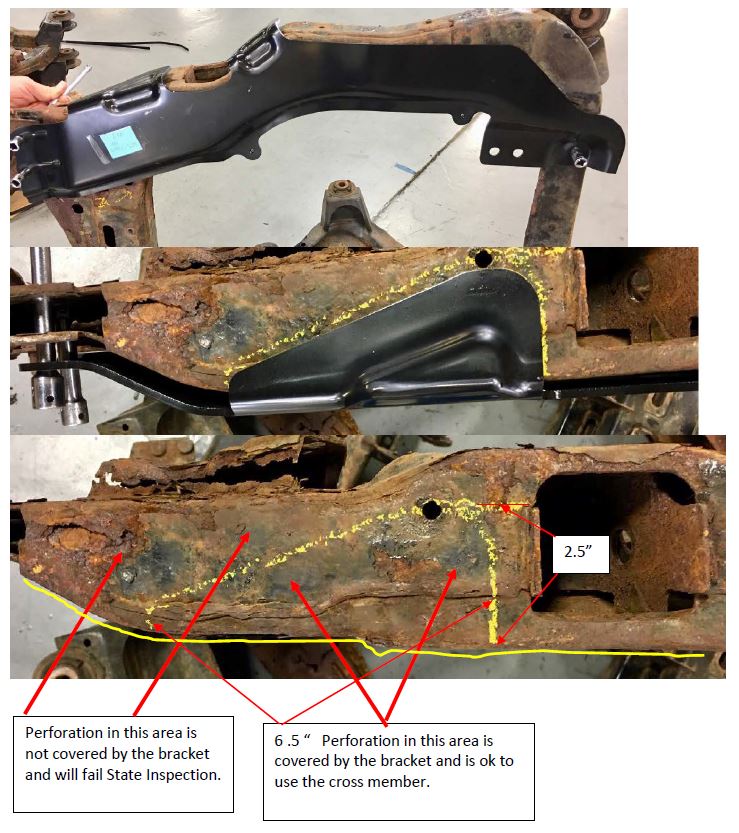

Additional Failure Examples of Zones 1 through 3

Photos of the bracket installation

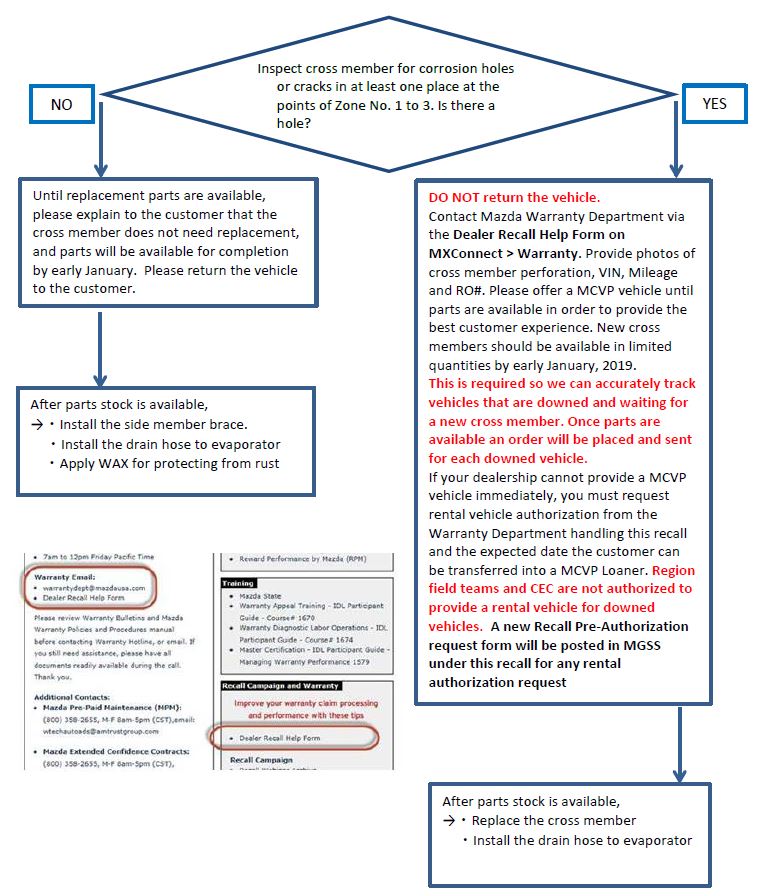

Process for handling failed inspections:

To help you effectively perform this inspection portion of the recall, Mazda has developed the following resources:

has developed the following resources:

- Inspection Procedures are available on MGSS (Mazda

Global Service Support) website via MXConnect.

Global Service Support) website via MXConnect. - For technical assistance, contact the Technical Assistance Hotline at (888) 832-8477, Option 3.

- For warranty questions, contact the Warranty Hotline at (877) 727-6626, Option 3.

- For Rental Authorization, Not MCVP, please use the Dealer Recall Help Form on MXConnect. Attach photos of cross member perforation, VIN, Mileage and RO#, and Recall Pre-Authorization form.

Warranty Inspection Information

| Inspection of the cross member only | ||

| Process Number | AJ047A | |

| Symptom Code | 99 | |

| Damage Code | 99 | |

| Part Number Main Cause | 7777-SP-P54 | |

| Quantity | 0 | |

| Labor Operation Number & Labor Hours | Operation No. | Labor hours |

| XXP8YXCX | 0.5 | |

| TO: | All Mazda Dealership General, Service, and Parts Managers Dealership General, Service, and Parts Managers |

| DATE: | September 14, 2018 |

| SUBJECT: | 2009-2010 Mazda6 – Front Cross Member Corrosion Concern Recall Campaign 2818I |

On September 14, 2018 Mazda Motor Corporation notified the National Highway Transportation Administration (NHTSA) to conduct a recall for a defect which relates to motor vehicle safety that exists in approximately 48,814 2009-2010 Mazda6 vehicles sold or ever registered in “Salt States”.

Motor Corporation notified the National Highway Transportation Administration (NHTSA) to conduct a recall for a defect which relates to motor vehicle safety that exists in approximately 48,814 2009-2010 Mazda6 vehicles sold or ever registered in “Salt States”.

What is the Problem:

On certain subject vehicles operated in the salt belt states, it is possible that the cross member may be corroded due to suspect insufficient paint coating. Corrosion may be more severe on the portion just under the air conditioner drain causing a perforation.

Continued use of the vehicle with such condition may allow the perforation to progress, and the support of the right lower control arm front bushing to decrease. This may result in a change of the right front wheel alignment. The driver may experience a heavy pull to the right, and in some cases, it is possible that the steering control may become difficult.

Parts for this recall are not yet available. In the coming weeks Mazda will work with the supplier to expedite repair parts for this concern. The purpose of this recall is to inspect the front cross member and install a side member (for reinforcement), replace the A/C drain hose, and apply rust proofing wax to the cross member. In severe cases the front cross member will be replaced along with the A/C drain hose instead of the side member.

will work with the supplier to expedite repair parts for this concern. The purpose of this recall is to inspect the front cross member and install a side member (for reinforcement), replace the A/C drain hose, and apply rust proofing wax to the cross member. In severe cases the front cross member will be replaced along with the A/C drain hose instead of the side member.

Owners of affected vehicles will be notified of this recall by first class mail no later than November 12, 2018. Inspection procedure and other information will be posted on MGSS next week when available. Repair Procedures, Parts and Warranty information and Owner Notification documents will be posted by November.

We apologize for any inconvenience this recall may cause you and your customers. Your understanding and support in carrying out this campaign is greatly appreciated.

Protect What is Important to You.

Sincerely,

Akira Ikemoto

Director, Technical Services Division

Mazda North American Operations

North American Operations

| TO: | All Mazda Dealership General, Service, and Parts Managers Dealership General, Service, and Parts Managers |

| DATE: | September 24, 2018 |

| SUBJECT: | ***UPDATE*** Interim Inspection Procedure Now Available 2009-2010 Mazda6 – Front Cross Member Corrosion Concern Recall Campaign 2818I |

An Interim Vehicle Inspection Procedure has been developed for those vehicles that arrive, or are currently at the dealership prior to the launch of the recall.

Interim Vehicle Inspection Procedure/Tracking:

Follow the Interim Inspection Procedure posted on MGSS. The vehicle should be inspected for corrosion holes or cracks in at least one place at specific points on the cross member. If the vehicle has been determined to need repair, please follow these vital instructions: Pictures will be required.

- DO NOT return the vehicle to the customer.

- Contact Mazda Warranty Department via the new Dealer Recall Help Form on MXConnect > Warranty.

- Provide photos of cross member perforation, VIN, Mileage and RO#.

- Offer a MCVP vehicle until parts are available in order to provide the best customer experience.

- If your dealership cannot provide a MCVP vehicle immediately, you must request rental vehicle authorization from the Warranty Department, and provide the expected date the customer can be transferred into a MCVP Loaner. A new Recall Pre-Authorization request form will be posted in MGSS under this recall for any rental authorization request.

- DO NOT request rental authorization from your District Field Manager or CEC (Customer Experience Center). The Warranty and Recall Operations teams will be tracking all downed vehicles.

- Submit an inspection claim through eMDCS

NOTE: New cross members should be available in limited quantities by early December, 2018. Once parts are available an order will be placed and sent for each downed vehicle.

We apologize for any inconvenience this recall may cause you and your customers. Your understanding and support in carrying out this campaign is greatly appreciated.

Protect What is Important to You.

Sincerely,

Akira Ikemoto

Director, Technical Services Division

Mazda North American Operations

North American Operations

Remedy Instructions and TSB

Loading...

Loading...

Miscellaneous Document – 2009-2010 Mazda6 – Front Cross Member Corrosion Concern Recall Campaign 2818I – Parts and Warranty Information on last page

Loading...

Loading...

Manufacturer Notice

October 3, 2018

Loading...

Loading...

***UPDATE*** Interim Inspection Procedure Now Available

September 24, 2018

Loading...

Loading...

Manufacturer Notice

September 14, 2018

Loading...

Loading...

Miscellaneous Document – Recall Rental and Additional Damage Pre-Authorization Form – FINAL

Loading...

Loading...

Miscellaneous Document – 2818I Tracking Form – Recall Rental and Additional Damage Pre-Authorization

Loading...

Loading...

Recall Acknowledgement

October 9, 2018

Loading...

Loading...

- Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

- Rubberized formula protects against corrosion and damage from water, salt and other chemicals

- Dries to the touch in 30 minutes and covers up to 10-12 sq. ft. per can

- Undercoating helps deaden sound and reduce damage to parts

- Features a wide, comfort spray tip and any-angle spray technology for easy painting even upside down

- Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

- Professional-grade formula provides superior protection against corrosion and damage from water, salt and other chemicals

- Dries to the touch in 1 hour and covers up to 10-15 sq. ft. per can

- Undercoating helps deaden sound and reduce damage to parts

- Features a wide, comfort spray tip and any-angle spray technology for easy painting even upside down

- Easy to use spray seals and protects metal surfaces from corrosion and moisture

- Flexible, rubberized coating provides superior chemical and abrasion resistance

- Dries to touch in 1-2 hours and covers 85-175 sq. ft. per qt. with rust protection

- Apply by brush, roller or spray to repair rust problems and prevent future issues

- Creates a protective coating with no shine, flat finish on rusted or bare metal

- MULTI-PURPOSE UNDERCOATING may be applied to cars, truck and recreational vehicles

- SOUND DEADENING PROPERTIES help reduce road noise

- ASPHALT-BASED product is excellent for wheel wells, quarter panels, interior fenders, under the hood and more

- PROTECTS THE UNDERCARRIAGE of vehicles from rust and abrasion

- AEROSOL DISPENSER allows for easy spray-on application

- Paintable & Top Coat Compatible: Easily paintable, compatible with most top coats for a seamless, customized finish.

- Ready-to-Spray & Fast Drying: Convenient, ready-to-spray formula dries quickly, saving time on application.

- 50-State VOC Compliant: Meets all 50-state VOC regulations, ensuring environmental compliance.

- Convenient 4-Pack Kit with Spray Applicator Gun: Ideal for multiple projects, including truck undercoating spray applications.

- FRAME COATING: This special aerosol spray is both a rust prevention and rust destroyer formula rolled into one. It will not only protect your chassis from the start of rust formation and allow you to maintain a clean finish, it also eliminates the need for any future maintenance or repairs, ensuring that it will be as good as new for years to come.

- HOW TO USE: Shake the can vigorously for at least 1 minute before and occasionally during use. Insert extension tube into spray nozzle then insert extension nozzle into frame openings, bolt holes, etc.Depress spray button and apply coating while pulling the extension nozzle back from the opening. Continue in all areas you can for complete coverage.

- EASTWOOD QUALITY: Eastwood offers solutions which combines our 4,000+ unique products with the know-how to “Do The Job Right”. With an In-house product design, development and testing and a strong track record of high-quality, innovative products. Used and trusted by top builders to beginners and also provides a Lifetime Tech Support.

- SAFETY INFORMATION: Always wear eye, skin and respiratory protection when applying this product.Use in a well ventilated area away from open flame. Store spray in a cool dry place. Warning: This product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

- WARRANTY: Comes with a 90-day limited warranty and 90-day return. Can not be sold in the state of California.

- Comprehensive Protection: Provides a durable, rubberized coating that safeguards vehicle undercarriages from corrosion caused by moisture, salt, and other environmental factors.

- Sound Dampening: Effectively reduces road noise by dampening vibrations, contributing to a quieter ride.

- Easy Application: The aerosol spray format ensures a uniform application without running, suitable for cars, trucks, and recreational vehicles.

- Professional Grade: Trusted by professionals for its high-quality formulation, delivering reliable performance in various conditions.

- Pack of 6: Includes six 16 oz cans, providing ample coverage for multiple vehicles or extensive projects.

- FLUID FILM BLACK offer powerful corrosion protection for all metals and superior lubrication for moving parts. The long lasting thixotropic liquids and gels is aptly used in the highly corrosive marine environment and vehicle undercoating in the automotive and snow handling industries

- HOW IT WORKS. The wet barrier creeps and migrates into tight seams and into the metal chassis to provide corrosion protection from salts and brines. Protects your vehicle while restoring a rich black color to the chassis or cover existing rust

- NO SOLVENT. Formulated from specially processed wool-wax, highly refined petroleum oils and selected agents, providing a non-toxic, non-irritating, non-flammable coating for corrosion control, penetration, metal wetting and water displacement

- WIDELY USED for maintenance of locks & hinges at home, lawn & garden tools & equipment, as well as in the aviation and automobile industries. In government and commercial facilities. Equipment in fishing, gas companies, farming, salt, power and industrial plants

- Versatile Pneumatic Application Gun: Ideal for automotive rust proofing, undercoating, chip guard, truck bed liner, and various oil, solvent, or water-based coatings.

- Precision & Texture Control: Lightweight, balanced, and precisely machined for applying different viscosity coatings and achieving various textures.

- Includes Two 22" Flexible Extension Wands: One multi-directional nozzle for hard-to-reach areas and hollow frames; one straight single-direction nozzle.

- Aluminum Body with Comfortable Grip & Air Regulator: Features a die-cast aluminum alloy body, easy-grip trigger handle for extended use, built-in air pressure regulator with gauge and a 25-ounce suction feed aluminum fluid cup.

- Designed for Professional & DIY Use: Suitable for both professional auto body shops and DIY enthusiasts looking for reliable coating application.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.