| “This site contains affiliate links for which OEMDTC may be compensated” |

2012-2013 MAZDA3 (WITH SKYACTIV) – CHECK ENGINE LIGHT ON WITH DTC P0300:00, P0301:00, P0302:00, P0303:00, AND/OR P0304:00

APPLICABLE MODEL(S)/VINS

2012-2013 Mazda3 (with SKYACTIV)

Check Engine Light ON with DTC P0300:00, P0301:00, P0302:00, P0303:00 and/or P0304:00 stored in memory.

- P0300:00: Random misfire detected

- P0301:00: Cylinder No.1 misfire detected

- P0302:00: Cylinder No.2 misfire detected

- P0303:00: Cylinder No.3 misfire detected

- P0304:00: Cylinder No.4 misfire detected

Carbon may be deposited around the intake valves, resulting in unstable engine combustion and misfiring during the accelerated warm-up system (AWS) operation.

REPAIR PROCEDURE

- Check the FFD and verify that it meets the following conditions.

- If it meets the following conditions, go to next step.

- If it does not meet the following conditions, follow the instructions for the DTC on MS3.

- One or more snapshots exist for P0300, P0301, P0302, P0303 or P0304

- (LOAD_C) : Above 70%

- (ECT) : Below 100 °F

- (RPM) : Above 1300 RPM

- (VSS) : = 0 MPH

- (SPARKADV) : -21 to -8

- (EG_RUN_TIME) : Below 00:45

- Decarbon the intake valves using the following “Intake Valve Deposit Decarbon Procedure”.

- Using IDS or Mazda J2534 96.04 or later software, reprogram the PCM to the latest calibration (refer to “Calibration Information” table) by following the “Module Reprogramming” procedure.

NOTE:

- Always update the IDS tool first, then follow on-screen instructions to download the needed calibration file for PCM reprogramming.

- It is not necessary to remove any fuses or relays during PCM reprogramming when the IDS screen prompts you to do so. You may accidentally stop power to one of the PCM terminals and cause the PCM to be blanked, or you may receive error messages during the IDS reprogramming procedure.

- IDS shows the calibration part numbers after programming the PCM.

- Please be aware that PCM calibration part numbers and file names listed in any Service Bulletin may change due to future releases of IDS software, and additional revisions made to those calibrations for service related concerns.

- When reprogramming a PCM, IDS will always display the “latest” calibration P/N available for that vehicle. If any calibration has been revised/updated to contain new information for a new service concern/issue, it will also contain all previously released calibrations.

- When performing this procedure, we recommend using the “Power Supply” mode in the Battery Management System to keep the vehicle battery up to capacity. If a different charger is used, make sure it does not exceed 20 AMPS. If it exceeds 20 AMPS, it could damage the VCM.

- After performing the PCM reprogramming procedure, verify the repair by starting the engine and making sure there is no Check Engine Light ON or abnormal warning lights present.

NOTE:

- If any DTCs should remain after performing DTC erase, diagnose the DTCs using MS3 online instructions or Workshop Manual section 01-02.

- After PCM reprogramming, it is no longer necessary to road test the vehicle to “relearn” KAM (Keep Alive Memory).

CALIBRATION INFORMATION

| Spec. | Transmission | File Name |

| CALIF ULEV | A/T | PSZH-188K2-B |

| M/T | PSZG-188K2-B | |

| FED/CANADA | A/T | PSZK-188K2-B |

| M/T | PSZJ-188K2-B | |

| CALIF PZEV | A/T | PE08-188K2-W |

| M/T | PUYG-188K2 |

NOTE: It is not necessary to order a PCM part for this repair procedure.

PART(S) INFORMATION

| Part Number | Description | Qty. |

| PE01-13-111 | Gasket, Inlet Manifold | 4 |

| PE01-13-655 | Gasket, Throttle Body | 1 |

Intake Valve Deposit Decarbon Procedure

Use cleaner 0000-77-129 (Wurth TUNAP 129)

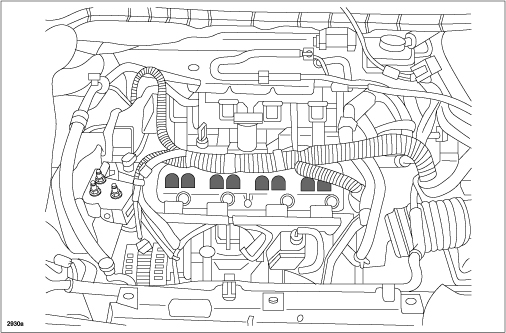

- Remove the intake manifold and spark plugs.

NOTE: DO NOT disconnect the negative battery cable to keep the misfire count active.

CAUTION: Take care not to break the harness clips.

- Check for carbon deposit around the intake valves.

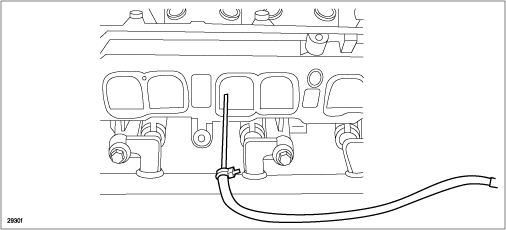

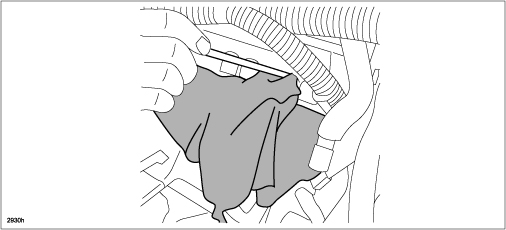

- Spread shop towels under the intake ports to protect components from cleaner overflow.

CAUTION: Take care not to damage the alternator.

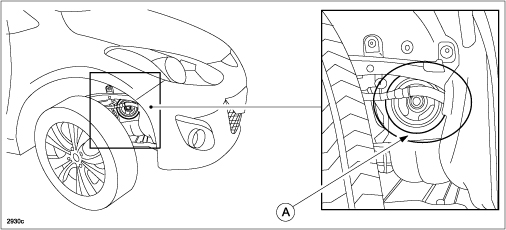

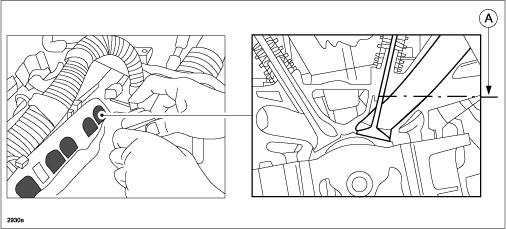

- Raise the vehicle and remove the right-front splash shield to access the crankshaft pulley (A).

- Perform the following to determine piston location and valve opening during cleaning.

- Rotate engine to TDC.

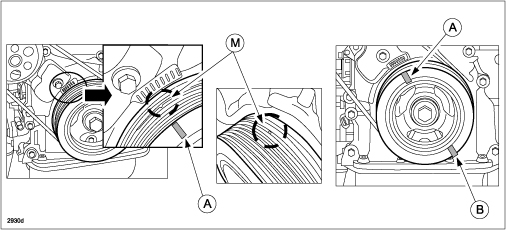

- Add a paint mark “A” to the pulley face at TDC.

- Add another paint mark “B” to the pulley face 180 degrees opposite from TDC mark (M).

- When mark A is located at TDC, the intake valves are closed at cylinders #1 and #4.

- When mark B is located at TDC, the intake valves are closed at cylinders #2 and #3.

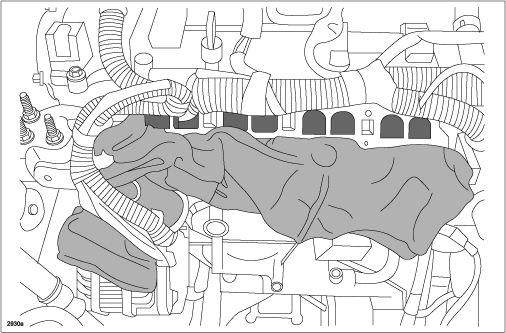

- Clean the intake valves of cylinders #1 and #4 with mark A at TDC.

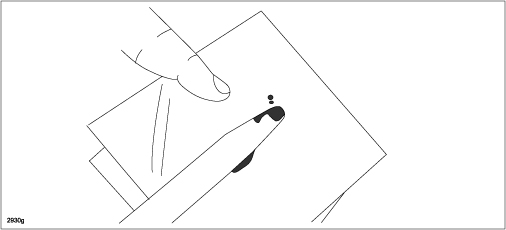

- Spray the cleaner fluid onto carbon deposit around the intake valves until fully covered (A) and let soak for 2 hours.

- Soak up the cleaner fluid with shop towels or a temporary suction tool.

- Scrape the carbon deposits off of the stems and intake valves using shop towels and an appropriate plastic or wooden stick.

CAUTION: DO NOT use a metal tool in order to avoid valve damage.

- Wipe out the scraped deposits with shop towels and the plastic or wooden stick.

- Clean the intake valves of cylinders #2 and #3 with mark B at TDC by repeating step No.5.

- Clean the cylinder head to intake manifold sealing surfaces.

- Reassemble the intake manifold and the other remaining parts.

- Crank the engine with the accelerator pedal fully depressed (Dechoke mode) for 10 seconds. Repeat this twice in order to clear the remaining materials in the ports.

NOTE: Dechoke mode cancels fuel injection during cranking (when the accelerator pedal is fully depressed).

CAUTION: White smoke may occur, therefore prepare the exhaust vacuum duct or perform this step in a well ventilated area.

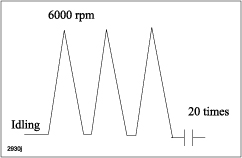

- Race the engine from idle to 6000 rpm by fully depressing the accelerator pedal 20 times in order to clear the remaining deposits and cleaner fluid.

Approved J2534 Device ![]()

![]() with Mazda J2534 Software FMP & MMP

with Mazda J2534 Software FMP & MMP

Mazda uses a very similar program to FMP, named MMP, MMP allows for reprogramming of PCMs only, no body modules.

uses a very similar program to FMP, named MMP, MMP allows for reprogramming of PCMs only, no body modules.

The security information is separate from the programming subscription and you must email information to Mazda for the Immobilizer/PATS codes.

for the Immobilizer/PATS codes.

Some reflashes require access to TSBs, and they are not included in the programming subscription.

The MMP software covers model year 1996 and newer models for reprogramming.

All 1996 models and up can be reflashed except for Miata. Miata (MX-5) could be reflashed starting in 2006.

- The application will determine whether or not a new calibration file is available.

- If you choose to use the new file, the module will be reprogrammed.

- If PATS functionality is required, it can be chosen from the toolbox.