| “This site contains affiliate links for which OEMDTC may be compensated” |

| Subject:

SQUEAK NOISE FROM FRONT BRAKES AND/OR GROOVE MARKS ON FRONT DISC PLATE | Bulletin No: 04-004/15 |

| Last Issued: 10/07/2015 |

BULLETIN NOTE

- This bulletin supersedes the previous bulletins 04-005/14 issued on 11/11/14, 10/28/14, 10/29/14, and 10/31/The APPLICABLE and PART(S) INFORMATION have been revised.

- Changes are noted below in Red beside the change bar.

APPLICABLE MODEL(S)/VINS

2014-16 Mazda3 with VINs starting with JM1

2016 CX-3

DESCRIPTION

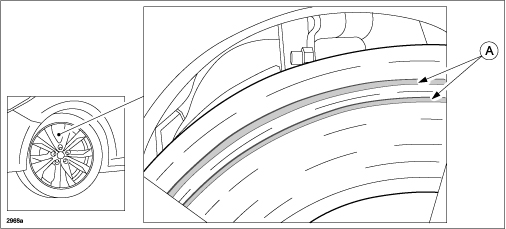

Some vehicles may exhibit a squeak noise when applying the brakes and/or groove marks (A) on the front disc plates. This is caused by abrasive metal from the front disc plate sticking to the brake pad, which damages the disc plate over time. To correct the problem, a modified brake pad is being used.

Customers having this concern should have their vehicle repaired using the following repair procedure.

REPAIR PROCEDURE

- Verify customer concern.

- Inspect the front brake pads and disc plates for damage and replace according to the inspection results as follows:

Front Brake Pads

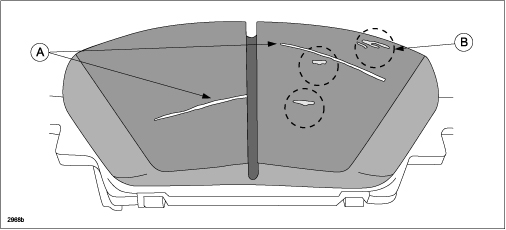

Visually inspect the front brake pads surface for pieces of metal.

- If metal pieces (silver or white in color) are found in a line (A) or cluster form (B) on the surface, replace the front brake pads with a modified service set.

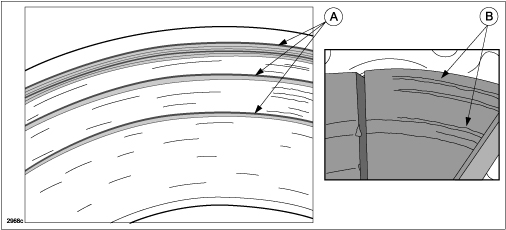

Visually inspect the surface of the disc plate(s) for damage.

- If groove damage is found on a disc plate (A) and brake pad (B), replace the front brake pads with a modified service set and ONLY the damaged disc plate(s).

NOTE: Metal may have dropped off the brake pad, and groove damage will be found on the brake pad in the same position as damage on the disc plate.

PART(S) INFORMATION

Mazda3

| Description | Qty. | Notes | Part Number |

| Front Brake Pad Set | 1 | All | BPY1-33-28Z |

| Front Disc Plate | 1 / One side | 2.0L | BPY1-33-251 |

| Front Disc Plate | 1 / One side | 2.5L | BHY3-33-251 |

CX-3

| Description | Qty. | Notes | Part Number |

| Front Brake Pad Set | 1 | All | BPY1-33-28Z |

| Front Disc Plate | 1 / One side | 2WD | BPY1-33-251 |

| Front Disc Plate | 1 / One side | 4WD | BHY3-33-251 |

WARRANTY INFORMATION

NOTE:

- This warranty information applies only to verified customer complaints on vehicles eligible for warranty repair.

- This repair will be covered under Mazda

’s New Vehicle Warranty.

’s New Vehicle Warranty. - Additional diagnostic time cannot be claimed for this repair.

Replacement of Front Brake Pads Only

| Warranty Type | |

| Symptom Code | 82 |

| Damage Code | 9D |

| Part Number Main Cause | BPY1-33-251 (2.0L)

BHY3-33-251 (2.5L) |

| Quantity | |

| Operation Number / Labor Hours: | XXK9LARX / 0.4 Hrs |

NOTE: Claim the brake pads as a related part number on all claims.

| Bulletin No: 04-004/15

0 2015 Mazda | Last Issued: | 10/07/2015 |

Replacement of Front Brake Pads and Disc Plate(s)

| Replacement of Front Brake Pads and one (1) Disc Plate | Replacement of Front Brake Pads and two (2) Disc Plate | |

| Warranty Type | ||

| Symptom Code | 82 | 82 |

| Damage Code | ||

| Part Number Main Cause | BPY1-33-251 (2.0L)

BHY3-33-251 (2.5L) | BPY1-33-251 (2.0L)

BHY3-33-251 (2.5L) |

| Quantity | 1 | 2 |

| Operation Number / Labor Hours: | XXK9LBRX / 0.5 Hrs | XXK9LCRX / 0.6 Hrs |

NOTE: Claim the brake pads as a related part number on all claims.

04-004/15

10/07/2015

Loading...

Loading...

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS, disc and drum brake systems

- Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- The information below is per-pack only

- High quality blend of polyethylene glycol ethers and additives

- Compatible with all brake system rubber components and other brake fluids

- Prevents seal hardening or softening

- Protects against rust and corrosion

- High quality blend of polyethylene glycol ethers and additives

- Compatible with all brake system rubber components and other brake fluids

- Prevents seal hardening or softening

- Protects against rust and corrosion

- Provides excellent lubricity

- Helps provide protection against brake failure from vapor lock

- Helps prevent corrosion in brake system

- Works with all brake system requiring DOT 3 fluids

- Exceeds federal motor vehicle safety standard No. 116

- Meets SAE spec. J1703.

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100 percent longer than DOT 3, 50 percent longer than DOT 4, and 10 percent longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

- Premium DOT 3 Brake Fluid has a minimum boiling point of 450°F

- Meets and exceeds DOT 3 and all other Federal and SAE specifications and standards for motor vehicle brake fluids

- Mixes with all DOT 3 approved brake fluids

- Designed for use in disc, drum and ABS brake systems

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid boiling and vapor lock

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

- The 336⁰F wet boil point and 521⁰F dry boil point exceeds common characteristics for DOT 4 brake fluids

- Provides corrosion protection in brake components

- Matches needs of all DOT 4 manufacturer recommendations

- Compatible with all DOT 3 and DOT 4 applications

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

’s New Vehicle Warranty.

’s New Vehicle Warranty.